In the world of industrial automation and process control, precision is everything. Whether you're using an analyzer to make measurements for process control or to comply with an environmental regulation, the accuracy of your measurement directly impacts product quality, operational efficiency, and safety. Yet, one of the most overlooked aspects of specifying the optimal analyzer is the quality of the process data used during selection.

Why Supplier Recommendations Depend on Accurate Customer Data

When specifying measurement devices, suppliers and manufacturers rely heavily on customer-provided process data to guide their recommendations. This data forms the basis for selecting the correct technology, choosing the analyzer package, and ensuring compatibility with the process environment.

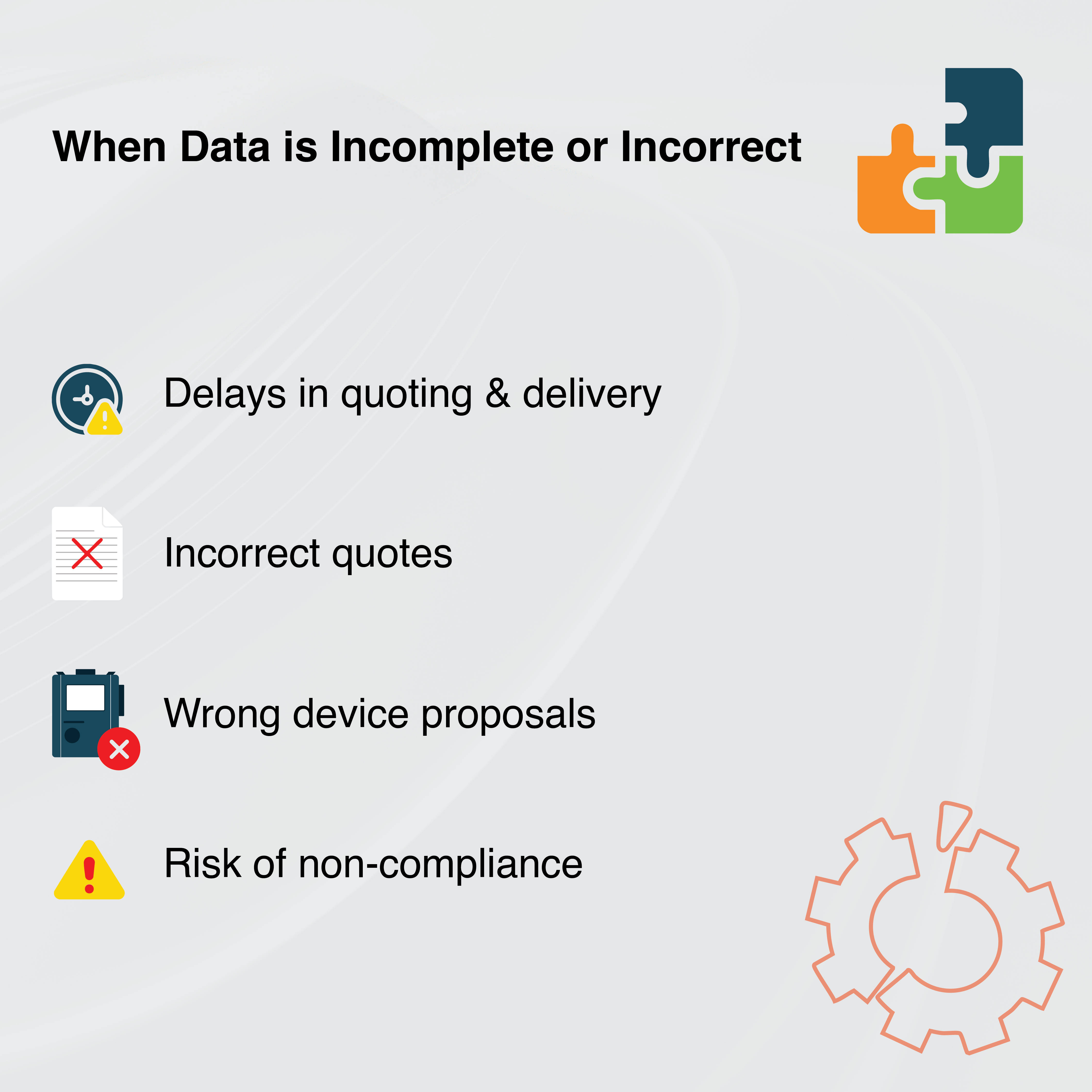

If the information provided is incomplete or inaccurate, several issues can arise:

- Delays in Quoting and Delivery

Missing details such as operating pressure and temperature ranges, chemical composition and phase (gas, liquid, slurry), environmental conditions (humidity, vibration, hazardous areas), installation constraints, or required accuracy and response time often require repeated clarifications, slowing down the procurement process.

- Incorrect Quotes

Without precise data, suppliers may quote for devices that do not meet the actual process requirements, leading to unexpected costs to correct the analyzer once installed

- Inappropriate Device Proposals

For example, recommending a flow meter designed for clean liquids when the process involves slurries or corrosive chemicals can result in premature failure and costly replacements.

- Risk of Non-Compliance

In regulated industries, incorrect specifications can lead to instruments that fail to meet safety or environmental standards.

How Accurate Data Improves Outcomes

When process data is accurate and complete, it enables:

- Optimal device selection: Ensuring the instrument operates within its designed range.

- Improved reliability: Reducing the risk of failure or drift.

- Lower lifecycle costs: Minimizing maintenance, calibration, and replacement.

- Better compliance: Meeting regulatory and safety standards with confidence.

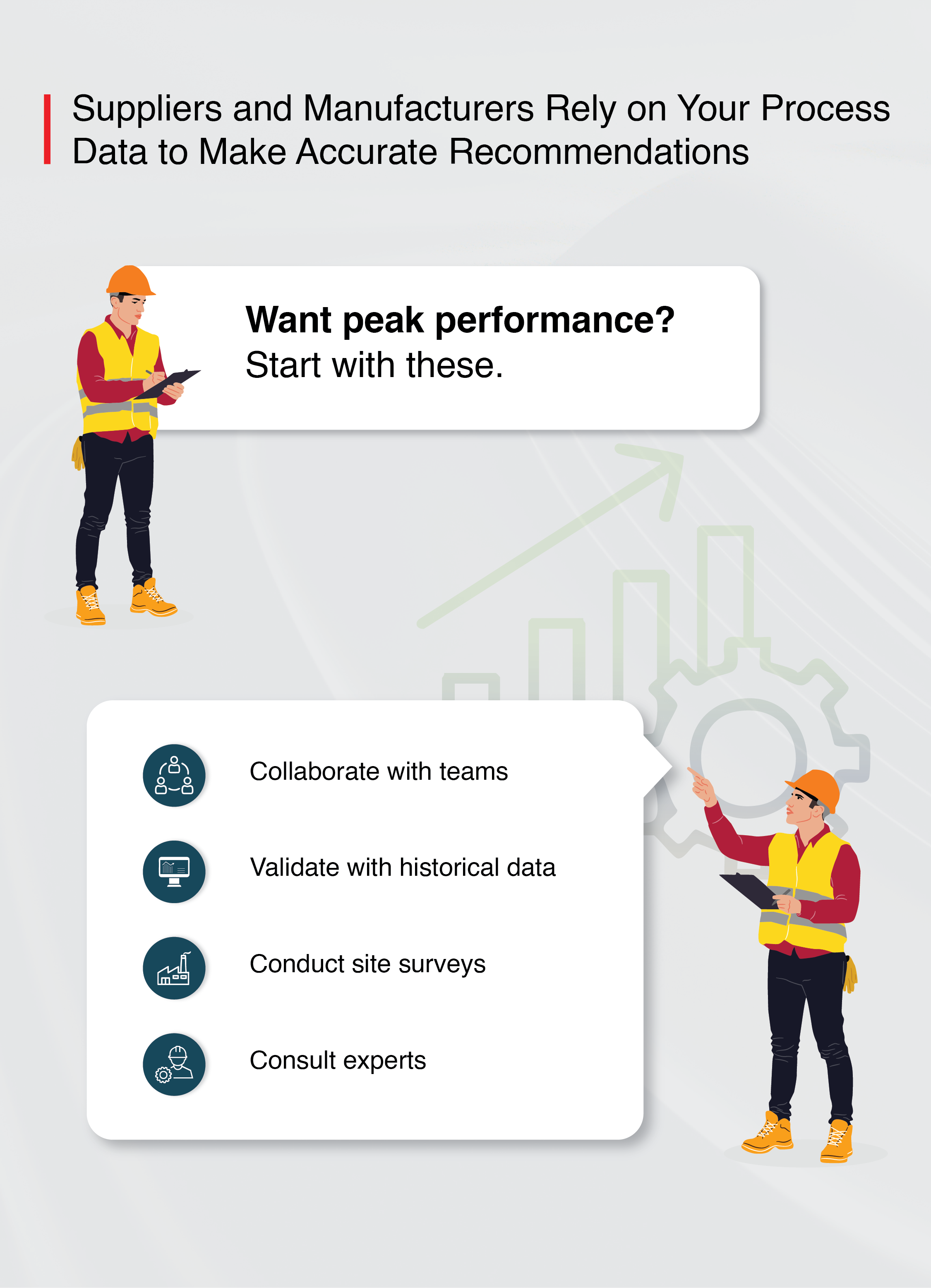

Best Practices for Gathering Process Data

To ensure accurate specification, consider these steps:

- Collaborate with operations and maintenance teams to understand real-world conditions.

- Use historical data from SCADA or DCS systems to validate assumptions.

- Conduct site surveys to assess environmental and installation constraints.

- Consult with manufacturers or technical sales support to interpret data correctly.

Conclusion

In instrumentation, the adage “garbage in, garbage out” holds true. Accurate process data is not just a nice-to-have—it’s the foundation of effective measurement. By investing time in gathering and validating this data, it enables suppliers to provide reliable, cost-effective, and compliant solutions. It reduces back-and-forth communication, accelerates delivery timelines, and ensures that the recommended device performs as intended in real-world conditions.